Service Process

From design concept to mass production, we provide complete semiconductor equipment manufacturing solutions

Manufacturing Process

Rigorous quality control process ensures that every process step meets the highest standards

Requirements Analysis

In-depth understanding of customer needs, formulating the most suitable manufacturing solutions

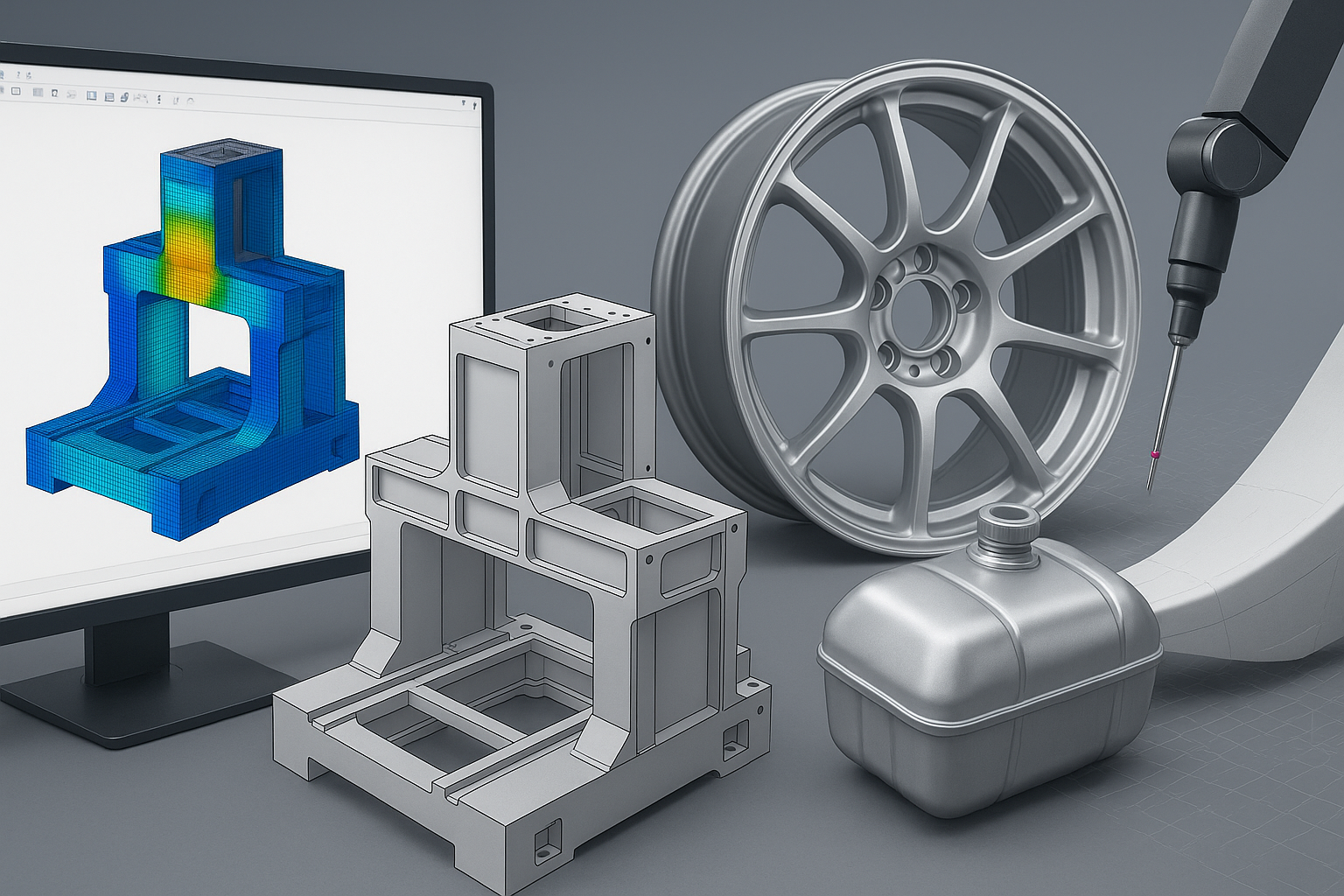

Design Development

Using CAE analysis technology for precision design and optimization

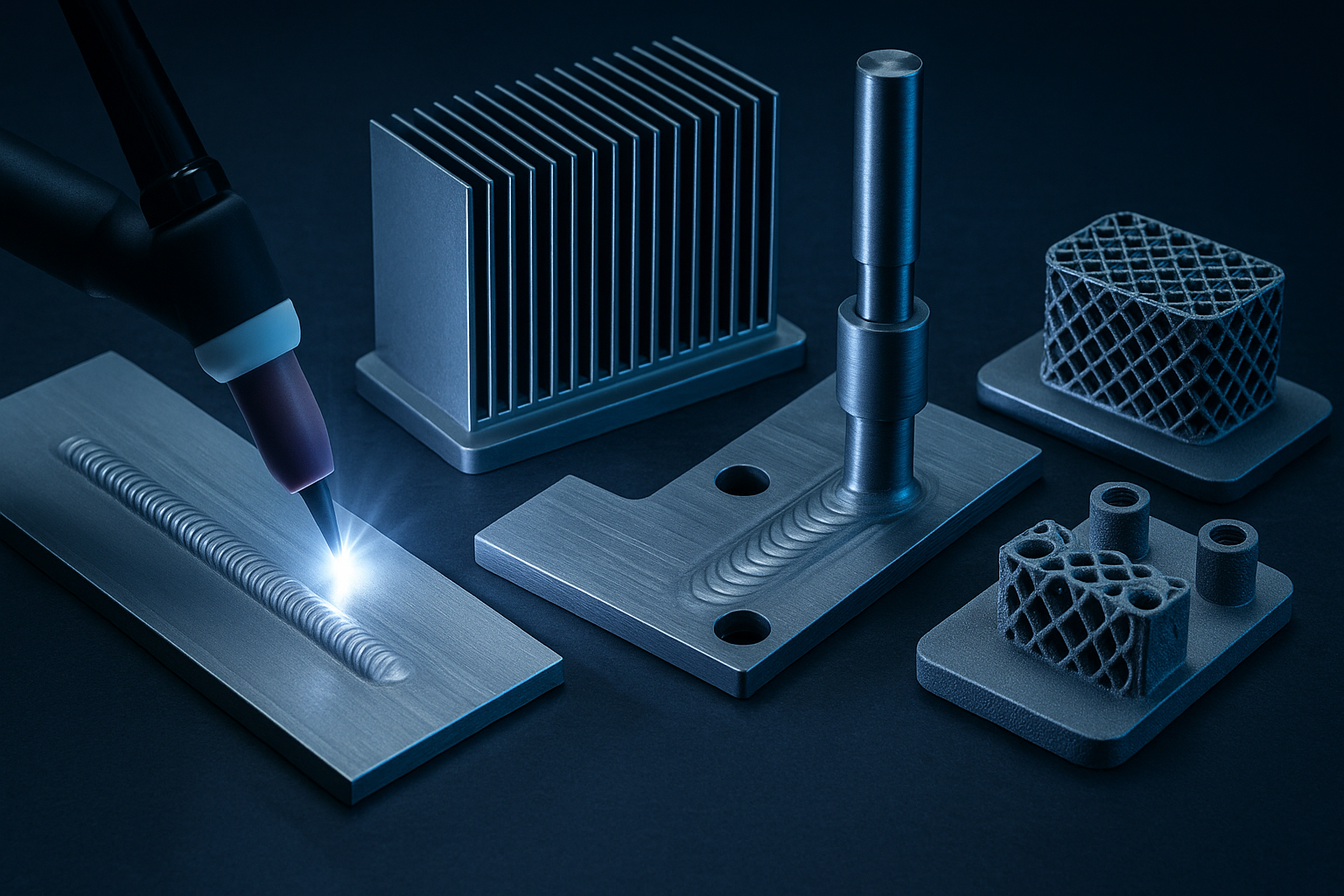

Precision Manufacturing

Adopting advanced process technology to ensure product quality and precision

Quality Verification

Strict quality testing to ensure delivery of highest quality products

Core Services

Professional semiconductor equipment manufacturing services to meet your various needs

Manufacturing Capabilities

We have comprehensive manufacturing capabilities, from material analysis, precision machining to clean room assembly, providing complete manufacturing solutions

Quality Certifications

Complying with international quality standards, providing reliable manufacturing service guarantees

ISO 9001:2015

Quality management system certification

LAM Certification

Semiconductor equipment manufacturer certification

AMAT Certification

Applied Materials equipment certification

Customer Testimonials

Customer success is our success, let's listen to their voices

Ready to Start Your Project?

Contact us to discuss your needs, we will provide the most suitable solutions

Contact Now